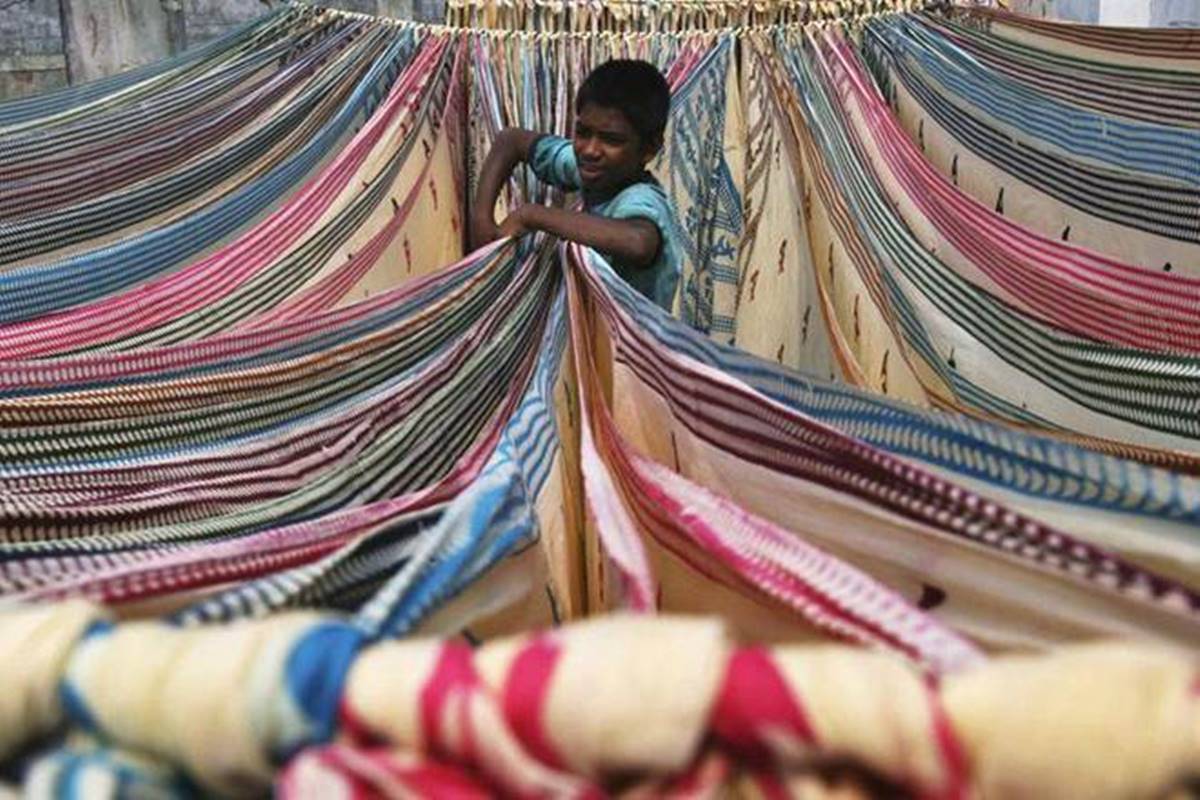

The majority of the textile industry is made up of the decentralized power loom, hosiery, and knitting industries. Contrasted with other industries in the nation, the textile industry is distinctive due to its tight ties to agriculture (for the supply of raw materials like cotton) and the old culture and customs of the nation. India's textile industry is capable of producing a wide range of goods that are suitable for various market niches both domestically and internationally.

While, on the other side, in India, the domestic garment and textile sector generates around 2% of the nation's GDP, or 7% of industry production in value terms. In 2020–21, textile, garment, and handicraft exports made up 11.4% of all Indian exports. India is one of the world's top producers of jute and cotton. 95% of the hand-woven fabric in the world comes from India, which is also the second-largest producer of silk in the world. According to estimates, the technical textiles market in India is about $16 billion, or around 6% of the worldwide market.